Multi-Use Die Cut Carton

This case study features one of our existing customers – a leading manufacturer of pressure relief safety systems in the UK. It’s essential that the fragile pressure discs our customer produces reach their destination in pristine condition, in the most ergonomic packaging available.

The issue

A change in packing staff and the shipping methods prompted the colleagues at this leading UK pressure relief safety system manufacturer to conduct a packaging review. The packaging review aimed to save money, rationalise materials and make the packaging process more efficient.

The packaging review identified:

- Significant packaging material use & waste

- Packaging time of 15 minutes per product

- Over 50 different packaging lines

- Cost per pack starting from £1.74 for the smallest of their products

Some packs used up to 13 layer pads at any one time, which often had to be cut to size or amended using band saws to fit the various dimensions of the pressure release disks. This meant packing wasn’t efficient as possible.

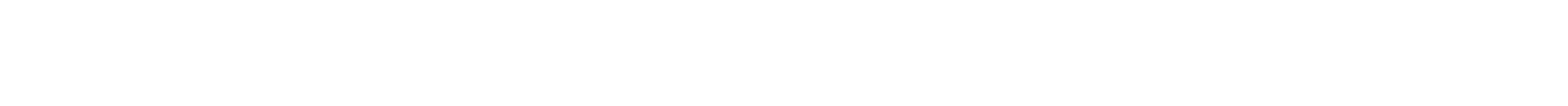

Previous pack used up to 13 layer pads

Our customer’s UK head office suggested using Korrvu packs. Whilst searching for Korrvu, colleagues at the manufacturer’s Midlands site came across Network Packaging and our relationship began.

Network Packaging initially supplied Korrvu packs, however it became apparent to our customer that these still weren’t fit for purpose and an even more efficient and cost effective solution was required.

The packaging solution

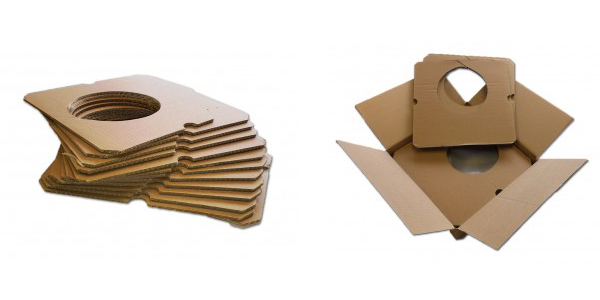

Having listened to and understood the issues our customer were experiencing, Network Packaging developed a range of multi-use die cut cartons, which allowed our client to pack their entire range of pressure release disks.

The range included only three cartons, meaning the manufacturer was able to completely rationalise all packaging materials.

The results

- Reduced costs – up to 68% overall cost reduction across the packaging range due to more cost effective materials being used

- Reduced packaging material use / waste – range of 3 core boxes allowed this pressure relief safety systems manufacturer to minimise its packaging range for the pressure release disks by 62%

- Increased packaging efficiency – packaging time reduced by 80% from 15 minutes per pack to 3 minutes per pack, increasing number of products packed per hour

- Saved storage space – a more compact packaging range means the manufacturer could release valuable storage space for use with other goods

- Re-directed resource – increasing packaging efficiency meant that less colleague resource was require and has since been allocated elsewhere in the business

If you’d like Network Packaging to review your packaging materials call us on 01902 496666 or email: contact@networkpack.co.uk.