As your business grows and customer demand increases, you may have started to think about the best way to pack your products quickly and efficiently. Whilst there are ways to optimise a manual packing operation, switching to packaging automation will maximise your speed.

Your initial thought might be that automation can be expensive. However, you’ll probably see return on investment within 6-12 months because of the advantages automation can offer. So, why choose packaging automation?

-

Improve productivity & gain more control

One of the main benefits of packaging automation is speed. This would enable you to increase your throughput and get more product out of the door. Plus, you’ll have greater control over the volume of materials being used and pack size. Productivity gains can also help you manage staff resources and labour cost more effectively.

-

Save storage space

Replacing multiple packing benches or processes with automation will mean you could reduce the space you need to pack your products. This will release valuable space and give you more storage. Using automation will also allow you to condense and streamline the packaging SKUs you’re utilising,

-

Reduce material waste & environmental impact

As mentioned, packaging automation gives you greater control. This means you’ll be using less packing material and creating less waste. This has a knock-on effect, as you’ll be reducing your environmental impact, sending less packaging into waste streams.

-

Minimise transport costs

Another advantage of automation is reducing your transport costs. Optimised pack sizes and less material being used will reduce the price you’re paying for transport. In addition, lower pack weights can help you reduce your transport emissions too.

-

Maximise product protection

Automated boxing, void fill and cushioning systems will ensure your products always have optimum protection This means your goods remain safe in transit and damages will be reduced.

-

Enhance customer experience

Customer experience can be everything. These days, your packaging can often be the first physical touchpoint your customers will have with your business. Automation can have a positive influence on customer experience due to improved pack appearance, dispatch speed and optimised protection.

Real results from packaging automation

We’ve worked with a wide range of customers to develop and install packaging automation solutions. Examples real results we’ve helped our customers achieve include:

- 50% labour cost saving by introducing new automated shrink-wrapping equipment

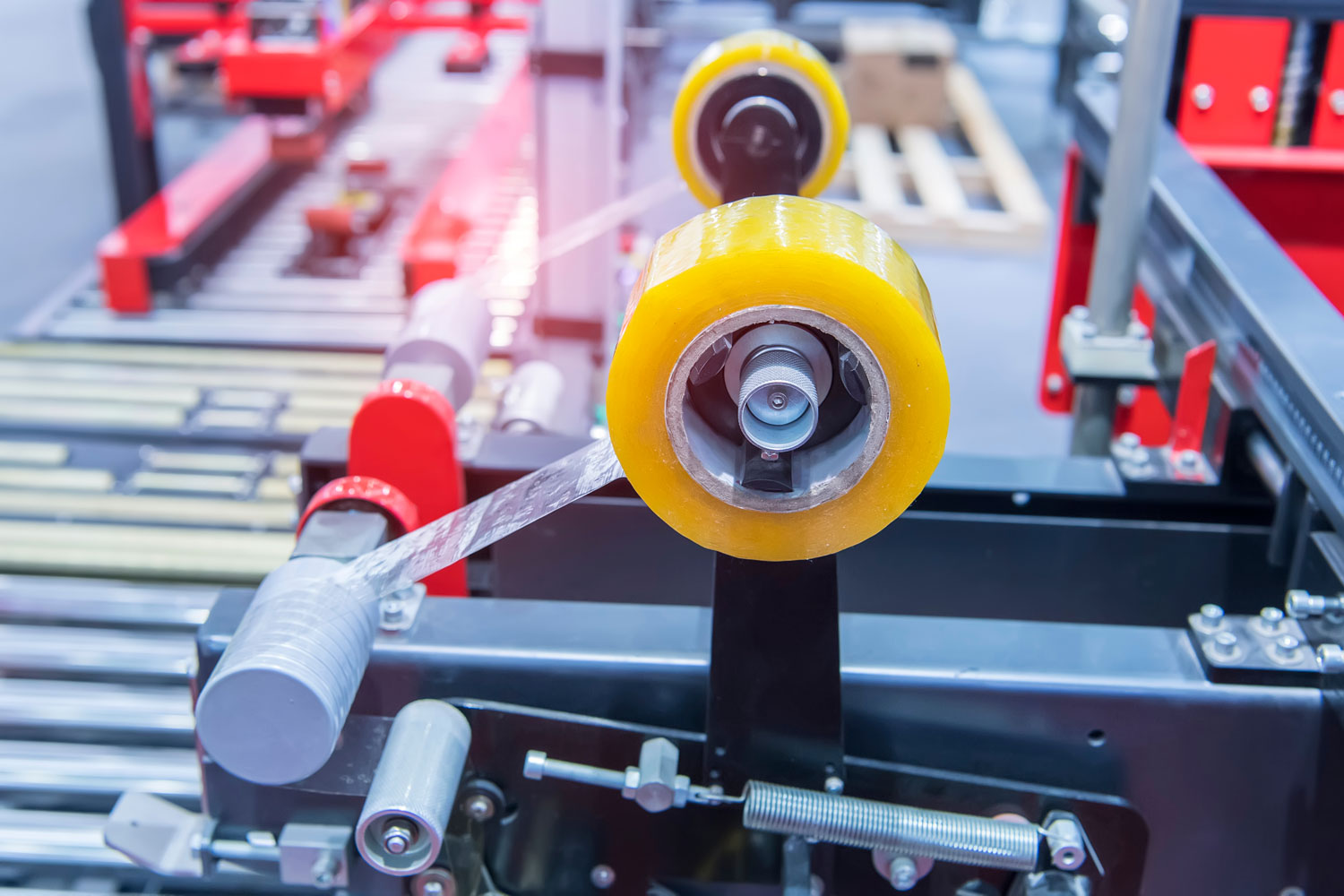

- Using a multi-point labelling system to double the number of packs produced per minute

- 30% reduction in material waste and costs by using an automated void fill solution

If you want to use packaging automation, we can work with you to develop solutions for your business. Book an appointment with our team by emailing contact@networkpack.co.uk or completing out contact form.