If you’re shipping items that need to remain chilled (between 2-8C°), making sure you’re packing them appropriately is essential. Your packaging material and how you pack your chilled products will help you maintain the in-pack environment, so your goods get to customers in the best condition.

The right packaging

First, you need the right packaging. To maintain a chilled in-pack environment, you’ll need:

- An outer box – the right size box is important, as excessive space in the box as big air voids can impact the in-pack temperature

- Insulating material – like foil lined bubble, Tempguard™ or Corritherm™, that help maintain the environment

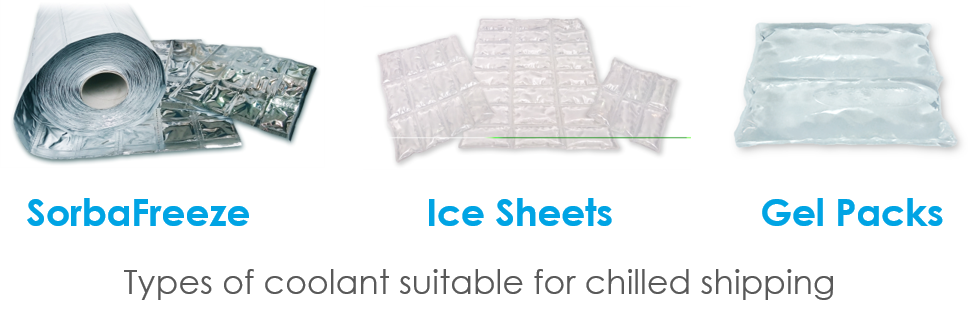

- A frozen coolant (like ice sheets or gel packs) – which will help keep everything chilled

If you’re aiming for a chilled delivery, you’ll need to use a coolant that is frozen to a temperature lower than the one you want in your box. This is because the coolant will slowly rise in temperature as the cold air it creates moves through the pack, so using a frozen coolant will ensure items are chilled for the duration of its journey.

The right packing technique

Now you’ve got your packaging, it’s time to pack your chilled products. Our group’s Temperature Controlled Packaging team recommend you assemble your pack as follows:

- Assemble your box and line it with your insulating material

- Next, pop your chilled goods into the pack

- Once your product is in place, you then insert the frozen coolant. Cold air is dense, so it moves downward, which is why we recommend it being put on the top of product, rather than underneath it. If you’re packing multiple layers of chilled product, you can interleaf layers of goods and coolant. You can also effectively pack coolant down the side of product, if there is room to do so

Coolant being packed after product

- After your goods and coolant are securely packed, you should fold the insulating liner over them tightly. This makes sure the temperature is maintained for as long as possible

- If needed, you can add a layer of void fill to the box, to add extra protection, but this should always be outside of the temperature controlled environment

- Finally, seal your pack and dispatch

Choosing the right transport

Speed is of the essence when you’re shipping temperature controlled goods. Depending on the packaging you’ve chosen, you’ll have a 24-48 hour window for your product(s) to reach its destination. Choosing a courier that can accommodate this will be essential.

Help with temperature controlled packaging

If you’d like advice about temperature controlled packaging, email contact@networkpack.co.uk or complete our contact form and our team will be happy to help