If you use packaging, the chances are that you will be using some sort of cardboard boxes in your packing operation. Cardboard boxes are the bread and butter of the packaging industry, but there’s actually a lot more to them than meets the eye.

There are hundreds of different box styles and grades of cardboard to choose from as well as style and size to factor in, so where should you start? Here’s a quick guide to cardboard boxes to get you going…

What’s in a box?

Most of the boxes you come across every date will be made from corrugated cardboard. Corrugated board is available in different material grades, varying paper weights and finishes. In its most basic form, corrugated board is made from three layers – an inner and outer liner, with fluted (waved) board in the middle.

Board types, grades, and fluting profiles

There are three primary types of corrugated board you’ll come across when it comes to boxes. These are:

- Single wall – one layer of fluted board is sandwiched between two sheets of liner board

- Double wall – two layers of fluting that are glued to three layers of liner board

- Triple wall – three layers of fluting are laminated with four liner boards

Boxes made from single and double wall are the most common and will cover most shipping needs. Triple wall boxes are for seriously heavy-duty applications, so you won’t come across them as frequently.

Board Grades

These board types can be made up of several board grades. The board grade refers to the weight, quality and type of material used to make the cardboard. You’ll find that the weight and/or quality of the board usually ranges from 125gsm to 300gsm, depending on what the box will be used for. The heavier the board grade, the stronger and more durable the box will be.

Many cardboard manufacturers now engineer performance boards that have properties equivalent to a heavier material but weighs less. Advances like this help you use less material and reduce overall pack weight. So, it’s worth remembering that GSM (grams per square metre) description may not be the actual weight of the cardboard but indicate the performance quality.

You may also here cardboard referred to as Kraft or Test. Kraft usually refers to cardboard that is manufactured from virgin paper pulp, whereas Test material is made from recycled content. Some boxes will combine both Kraft and Test board.

| Example Board Grades | ||

| Type of Material | Description of board quality / performance | Actual GSM weight |

| Brown Kraft | 125, 150, 200, 300 | 115, 140, 175, 280 |

| Brown Test | 125, 150, 200, 300 | 117, 140, 186, 275 |

| White Kraft | 120, 150, 180 | 115, 140, 175 |

Fluting Profiles

The waved middle liner in a piece of cardboard is available in a variety of different flutes. Fluting profiles are referred to by different letters or combinations of letters (for double or triple wall boxes). The difference between each type of fluting is the width between the waves in the board and the depth or thickness of the waves…

You’ll find that the most common fluting used is B or BC, however a packaging expert can recommend which fluting your box needs depending in application.

How about design? Choosing your box style….

In addition to the grade of cardboard your box is made from, there are also standardised designs (or styles) of box to choose from. These are dictated by FEFCO – the European Federation of Corrugated Board Manufacturers.

The FEFCO code is the internationally applied system for corrugated and solid board packaging design. It contains the design of the most common box types with a code number assigned to each design. There are nine different categories, which are:

- 01 – Commercial Rolls and Sheets

- 02 – Slotted Type Boxes

- 03 – Telescope Type Boxes

- 04 – Folder Type Boxes

- 05 – Slide Type Boxes

- 06 – Rigid Type Boxes

- 07 – Ready Glued Cases

- 09 – Interior Fitments

Of these categories, slotted type boxes and folder type boxes are most common. Within each FEFCO category, there are variations on the basic box style.

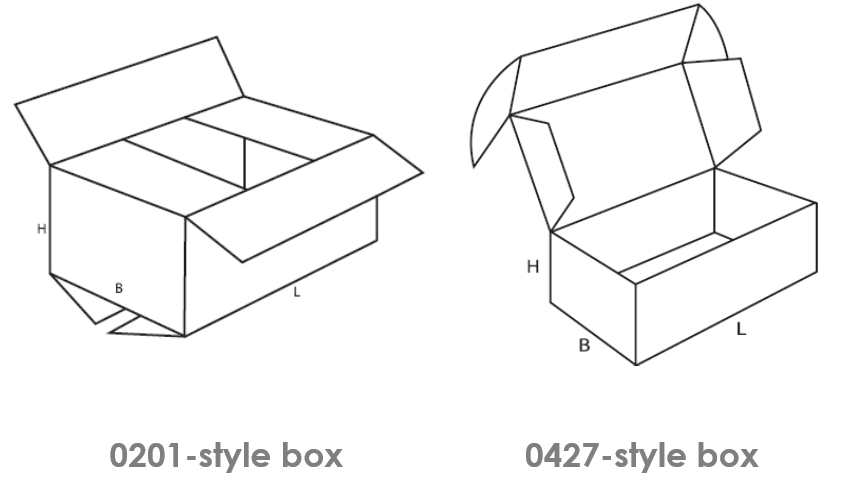

Slotted type boxes consist of one piece of board with a glued, stitched or taped joint, and top and bottom flaps. They are supplied flat and you need to seal the top and bottom flaps to close them.

Slotted type boxes consist of one piece of board with a glued, stitched or taped joint, and top and bottom flaps. They are supplied flat and you need to seal the top and bottom flaps to close them.

Folder type boxes are also made from one piece of cardboard. The bottom of a folder style box is hinged to form two or all side walls and the lid.

The 0201-style box is the most popular box from the slotted category, whereas an 0427-style carton is the most often used folder type box.

Just like with the board grade and fluting profile, the style of box you’ll need will depend on what you’re using it for.

How big should your box be?

One of the most important things you’ll need to know is the size of the box you want. This will need to accommodate the product(s) you’re packing. Therefore, most box sizes you’ll see refer to the carton’s internal dimensions – as this is the usable space.

To correctly measure a box, you need to measure the length, the width and then the depth. We always recommend measuring these dimensions in millimetres.

Putting it all together…

Once you have all this information, you have the basis for your overall box specification. For example, a basic slotted type double wall box could be listed as: 0201 / 125KTBC / 500 x 300 x 300. In order this indicates the box stye, the board grade and flute and the size of the box.

As well as your basic box specification you ma

Help choosing the best box for your business

If you need help deciding what box (or boxes) to use for your product, we can help. Our expert team can recommend what style of box and board grade will work best for you. Email contact@networkpack.co.uk or call 01902 496 666 with your enquiry.