Boxes are the most common packaging you’ll come across. We all use them – to move to a new house, to send parcels or even for storage.

So, if you need to get some boxes made, what do you need to know?

When we’re developing boxes with our customers, there are five key things we need to know:

1 – The box size

The first thing you need to know is the size of your box. In the packaging industry, we always refer to the internal box dimensions rather than the outer dimensions.

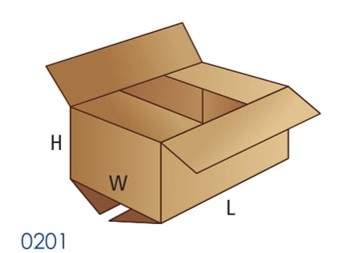

To correctly measure a box, you need to measure the length, the width and then the depth. We always recommend measuring these dimensions in millimetres. For example: 600mm x 300mm x 250mm.

Remember, the size of the box you want can affect the minimum order quantity. For example, the smaller the box, the higher the minimum order, as you can get more small boxes out of one sheet of cardboard when the design is cut out.

2 – The box style

The second thing you should know is the style of box you need. When we talk about box style we mean the type or shape of box you want. In Europe, the styles you can choose from are standardised within the packaging industry by the European Federation of Corrugated Board Manufacturers (FEFCO).

The most common box styles you’ll come across are 0201 and 0427 styles. You’ll sometimes hear the latter referred to as a “pizza box style. To see the full FEFCO box style guide, click here.

3 – The board grade

Next, you’ll need to know what board grade you require. Corrugated board is available in different material grades, varying paper weights and finishes.

Standard paper finishes include kraft, white and test (recycled). Paper thicknesses start at 125gsm and increase up to 300gsm.

As well as the finish of your board, you also need to decide the fluting. This determines the depth of the board. You can also choose from a variety of different flutes, depending on the strength of material you require. The most common flute profiles are C flute (3.5mm – 3.7mm thick) and B flute (2.7mm – 2.9mm). You can choose to have boxes made in single, double or triple wall.

4 – Plain or printed?

You also need to decide if you’d like your boxes plain or printed with some kind of reference or even your branding.

For full impact, you can choose to have your boxes printed inside and out. The design and number of colours you require will affect the printing process and associated costs, like printing stereos.

5 – The quantities you require

Lastly, it’s always useful to have an idea of the number of boxes you require of each size and design you need. This helps guide the manufacturing options you’ll have and will impact any volume discounts that can be offered to you.

Need help developing your boxes?

Our packaging experts can help you decide what boxes are best for your business. Book a consultation today by calling 01902 496 666, emailing us or completing our contact form.