If you’re palletising your goods, you probably use stretch film to help you secure the load.

You might think of stretch film as everyday packaging. However it can be an important factor in supply chain. In fact, using the right stretch film can have a real impact on your load retention.

So, why is load retention important?

Load retention can impact health and safety, your product integrity, your shipping and transport, and your costs.

Healthy & Safety

In the UK alone, there was over 600,000 workplace injuries during 2016/2017 (1). Ensuring your pallets are loaded and secured properly is essential in minimising the risk of a workplace accident. Pallets loaded too high or wrapped loosely can lead to tipping or goods falling from pallets. The right stretch film will give you load stability.

Product Integrity

Inefficient stretch wrap application can compromise your product integrity. For example, poor load retention could lead to crushing or product damage in transit. Using the right application method will protect your product integrity, control material usage and minimise waste.

Shipping & Transport

When your load retention is spot on and your pallets are planned effectively, you’ll be able to minimise transport costs. An efficient stretch application can control film usage, which can lessen your pallet weight and in turn reduce CO2 emissions during transit. If you have good load retention it will also contribute to road safety – as fewer accidents will be caused by loads tipping in transit.

Optimising your stretch wrap for effective load retention

Review the type of stretch film you’re using – cast, blown, pre-stretch, film thickness – there’s lots to factor in, as well as hand and machine grade films

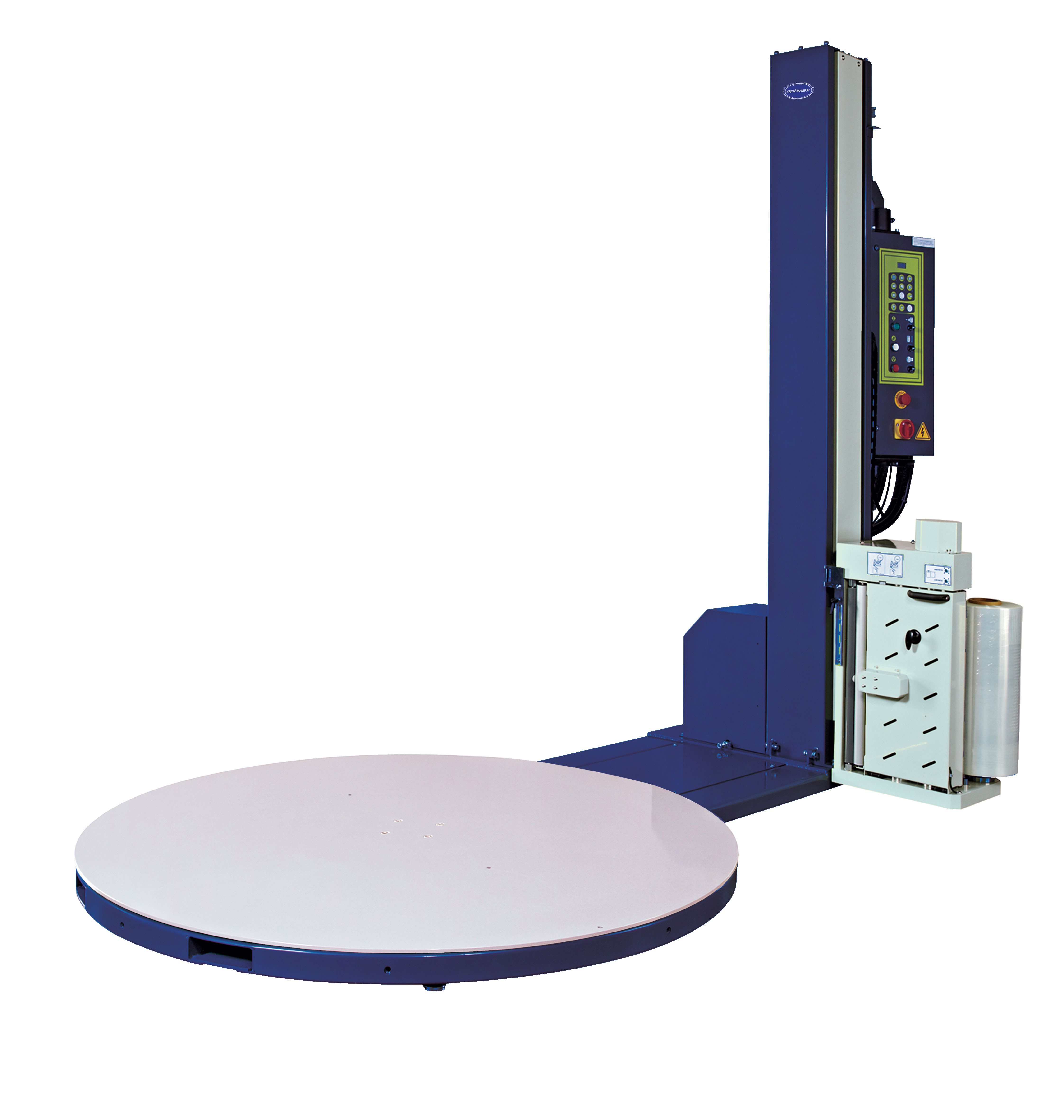

Review your stretch application method – there are lots of application tools and machinery for stretch film. If you’re a smaller business manual application tools are probably ideal, but in a high demand environment, you should consider automation

Conduct load retention testing – testing your load retention and safety will act as a quality check and help you identify any key areas for improvement

How do you test load retention?

There are several ways you can test load safety, including:

1. Force & puncture tests – these tests review the strength and durability of your stretch film and can identify how long it takes for your film to lose its retention

2. Vibration, impact and pitch & roll testing – this testing mimics the physical shakes, knocks and forces loads will be subjected during transit and investigates the reliability of your packaging in these situations

3. Climate testing – if you’re shipping your goods in temperature controlled environments, climate testing can help you see how the your film will react to various temperatures

Need support from packaging experts?

If you’d like to review your load retention, book an appointment with our team. Simply call 01902 496 666, email us or complete our contact form with your enquiry.

Source