At face value, packaging automation may seem like a big financial investment. Why spend budget getting machines to do what we can do ourselves? In fact, whilst there is an initial outlay for automating some or all your packing process, it can provide a great return on investment.

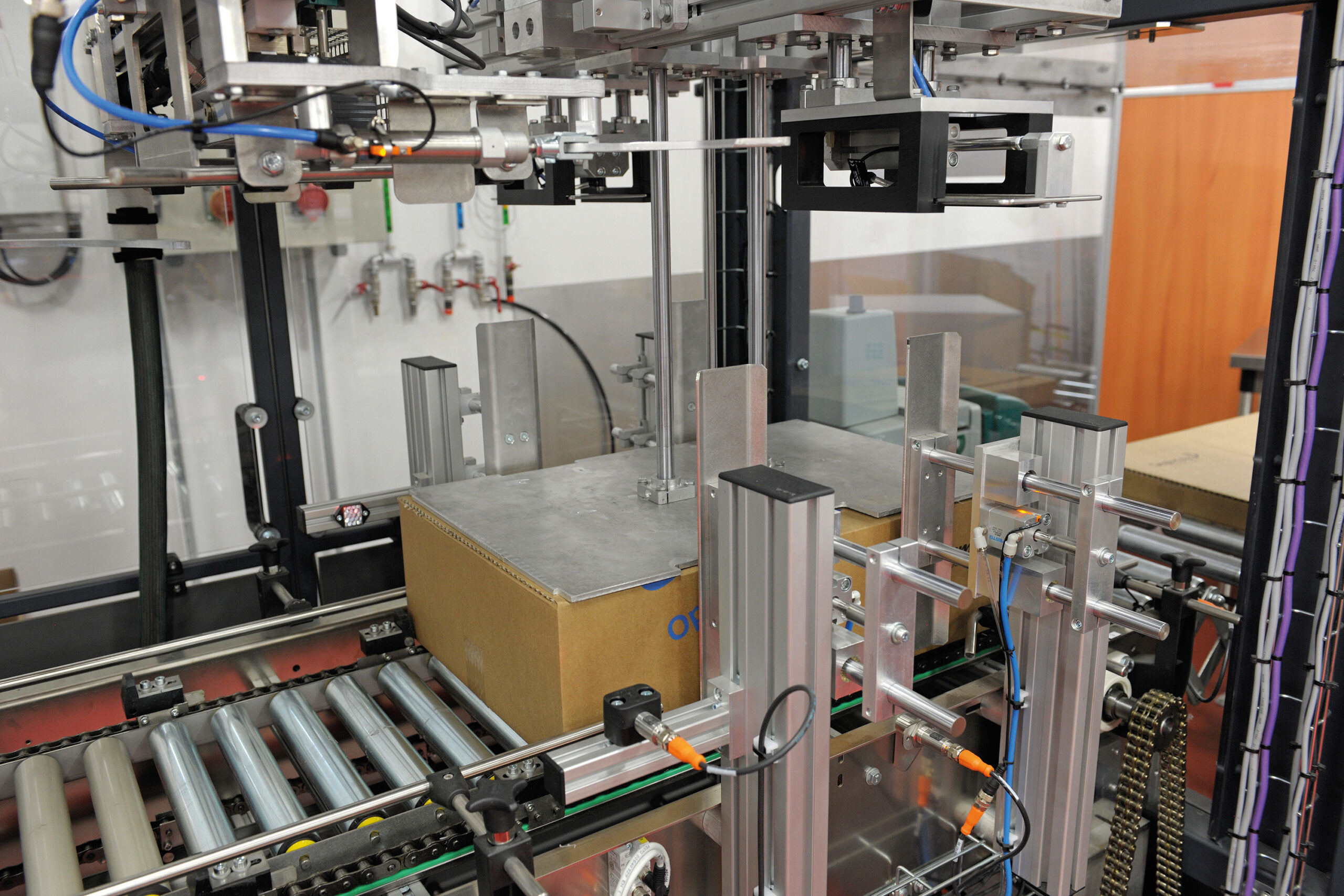

You can automate almost any part of your packing process, including boxing, bagging, taping, wrapping, filling, and labelling. The most obvious benefit of automating these processes is the dramatic productivity improvement you’ll gain, but it can also help you save money.

-

Minimising material waste, environmental impact and cost through efficiency

Using automated packing process will mean exactly the right amount of packaging is used every time. This will massively reduce the amount of waste you’re creating and drive down your material costs, as you won’t be using material unnecessarily. Another benefit of this is that your impact on the environment will be minimised too!

-

Lower labour costs by becoming more efficient

Introducing automation will make you more your packing processes more efficient. Your throughput will increase and the number of physical operators you need for your pack line may reduce. As a result you’ll be able to save money when it comes to labour.

-

Release space and cash tied up in stock

When you use packaging automation you can rationalise the number of packaging SKUs you need to keep in stock. This is because many automated packaging machines can accommodate packing a range of different size products. So, you’d need to keep less stock on site, saving you space. Plus as you’d require fewer packaging SKUs you’d have less cash tied up in packaging stock.

To learn more about the packaging automation, click here. If you’d like help automating your packaging processes, email contact@networkpack.co.uk or call 01902 496 666.