If you’re wrapping pallets to ship your goods, using the right film is essential. Using the right equipment is too! The correct stretch wrapping equipment will help you work efficiently, secure loads effectively and get the most out of the film you’re using.

Here’s a quick guide our team have put together to help you see what stretch film application methods you should be using in your packing operation….

Hand Tools

If you’re palletising goods every now and then or just a few times a week, you’ll probably be safe using hand film and hand tools. Equipment for applying film by hand comes in lots of different shapes and sizes. If you’re using smaller rolls (around 100mm wide), a simple, low-cost handy wrap dispenser is all you’ll need.

For full size rolls, you can choose from standard and bow dispensers, which can help you reduce hand strain. You can also get dispensers that are adjustable if you’re using different roll sizes.

Your usage: 1 – 4 pallets being wrapped a day (or less frequently)

Mobile Manual Pallet Wrappers

A compromise between basic hand tools and automating your pallet wrapping process is to use a mobile manual pallet wrapper. This type of equipment usually comes in at less than £2,000, so is more affordable

The manual wrappers are ideal if you want to improve the health and well-being of your workers – it stops them bending, limiting the possibility of back injuries. These mobile wrappers can also be moved around and stored where ever is easiest for you, plus they offer a bit more control, helping you save film.

Your usage: 5 – 9 pallets being wrapped a day

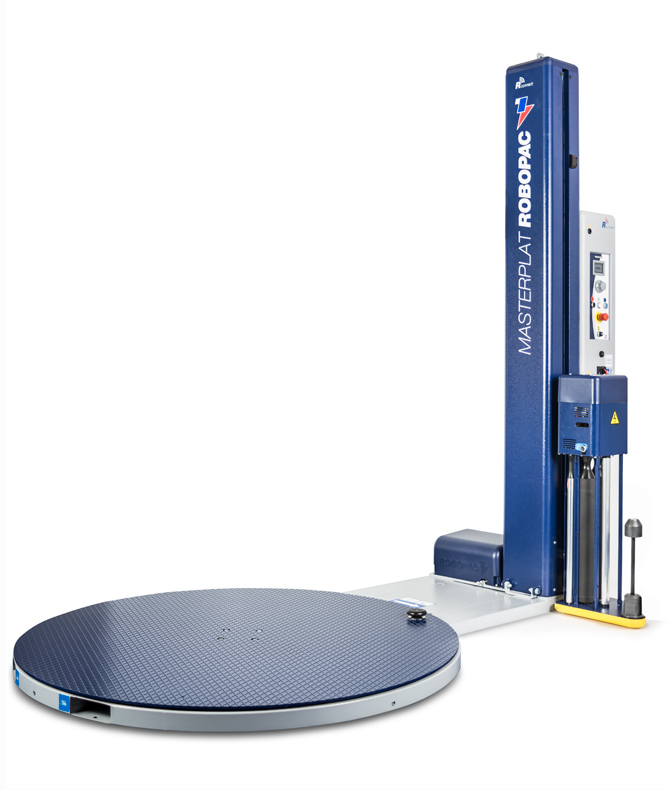

Stretch Wrapping Machines

If you work in a high demand environment that requires wrapping a lot of pallets or are being slowed down by hand application, it’s time you consider investing in a stretch wrapping machine.

Whilst the initial cost of the machine might seem daunting, it can actually save you money in the long run. You’ll save money as your can cost to wrap a pallet with reduce. This is because your material yield is controlled by machine settings, rather than human application.

The type of machine you go for will depend on several factors including the size and shape of products you’re palletising, your most common load profiles, and the space you have. For example, if you’re securing large or unusual profile goods, a robot wrapper might be a good choice.

Your usage: 10+ pallets being wrapped a day

Advice on your wrapping equipment

So, if you need help choosing the right wrapping equipment for your business, get in touch with our team. We can visit your site to help you decide what’s the best equipment to use. Plus we can make film recommendations with our free stretch film review process. Email contact@networkpack.co.uk or complete our contact form today.