Packaging automation is a great way to optimise your supply chain. It can help you pack faster, ship more product, and reduce labour costs. Automation can even help provide efficiencies in areas like transport and storage, depending on the solution.

So, what do you think about when you consider packaging automation? A lot of customers we speak to think that automating your packing processes will be expensive. They often believe it can be time consuming and require large machinery. But in reality, there are lots of quick and cost-effective packaging automation options available.

We’re want to show you that packaging automation doesn’t have to be complex or costly. To help you out, we’ve curated a range of quick to install packaging automation solutions that don’t cost the earth:

-

Water activated paper tape dispensers

Introducing a water activated paper tape dispenser is one of our go to suggestions for customers. It can help boost your productivity and control material use. There are number of different dispensers available and most will fit easily on to your packing stations and cost less than £1,500.

In practice, switching to water activated tape (also known as gummed paper tape), helped one of our customers achieve a 13% cost saving per pack. The swap also reduced the amount of sealing material they were using by 75%. Click to read the case study.

To see the other advantages using water activated paper tape can offer, click here to read our article 6 reasons to choose water activated tape.

-

Compact on-demand void fill machines

If you use manual void fill like packing peanuts or bubble wrap, upgrading to a compact on-demand void fill machine could help you save time and increase operational efficiency. Many tabletop void fill systems can be retrofitted to your existing packaging benches. This means you won’t need to shell out for an entirely new packing set up.

Plus systems like this can be rented on a monthly basis to help spread costs too. Plus, if you’re using a high enough volume of material, you may be able to use equipment free of charge subject to minimum usage agreements.

-

Battery operated strapping tools

Using a battery-operated friction welding tool to fasten your strapping a simple way to increase your packing speed. An option like this doesn’t require the same level of investment as a completely automated strapping table but still gives you an edge compared to manual sealing and cutting.

The range of Optimax® tools we supply are lightweight, have a high battery capacity for increased productivity and are portable – so you can use it anywhere in your warehouse.

-

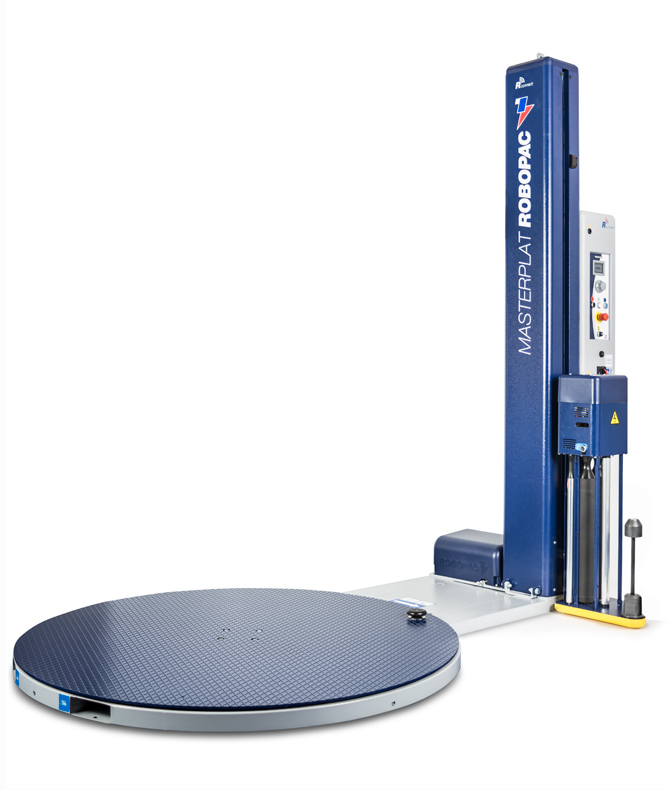

Automated pallet wrappers

Wrapping a lot of pallets manually can be incredibly time consuming and create unnecessary waste. The cost to wrap your pallet will vary significantly, as it’s all down to human operation.

Introducing an automated pallet wrapper combined with performance film is often a quick way to reduce film wrapping costs and speed up your supply chain. Whilst you might need to invest up to £5,000 in a machine initially, you could cut your film costs by up to 50%, so you’ll receive a pretty swift return on investment.

Click here to read more about our stretch wrap analysis service that can help you choose the optimum film and equipment for your business.

Help with your packaging automation journey

We’re helping businesses like yours with packaging automation every day. Almost any packing process can be automated including boxing, bagging, sealing, wrapping, and filling.

If you’d like to know more about the automated solutions we’ve curated in this blog or need help with any part of your packing process email contact@networkpack.co.uk.