Packaging essentials for plastics manufacturers

Did you know that manufacturing in the Midlands is booming? In fact, it accounts for “14.8% of the region’s output, well above the national UK average” (1).

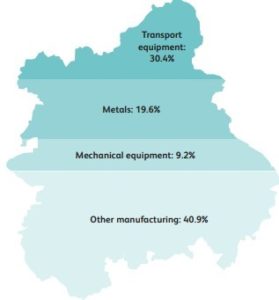

Split of manufacturers by sector in the Midlands (1)

In fact, plastic manufacturers contribute £23.5bn turnover to the UK economy and there are over 6,200 companies in the sector (2). With this in mind, if you’re a plastics manufacturer, are you protecting your goods?

Our experts got their heads together and have looked at the common challenges we help plastics manufactures with, as well as the essential packaging materials and key tips to help you make the best choices when it comes to packaging.

So, what packaging materials are essential for plastics manufacturers?

Packaging Challenge |

Essential Materials |

Our Tips |

What you’re shipping out is very heavy |

If that plastics you’re manufacturing are heavy, it’s essential you invest in quality boxes. Strong and durable double or tri-wall boxes will be able to bear the weight of anything you’re packing. |

One of our team could come and visit you to see your pack line in action, and recommend the best packaging solutions possible to help you increase efficiency and save money. |

You need to make sure your goods are properly protected |

When you’re shipping products that are slightly more fragile you should consider options like blocking, bracing or even foam inserts. Not only would this reduce the costs of damages and returns, it can improve you customer experience. |

For more detailed information on these products, check out our handy protective packaging guide by clicking here. |

You’re trying to be less wasteful |

You may use void fill to protect your goods in their box. If you feel like you’re using too much, and sustainability is something you’re working towards, we can supply a range of environmentally friendly void fill options, like Geami PadPak and other paper options! |

These things will not only reduce your customers wrap rage, but will also bring down the total cost of your packaging. |

You produce plastic sheets and stack them for transit |

When you’re producing and stacking plastic sheeting, you’ll need to use layer pads. They help to protect the integrity of the plastic by ensuring the weight is dispersed evenly when palletising. They’re available in either single wall or double wall, and a range of sizes. |

If you need extra protection for the edges or corners of your plastics you can also use edge protectors. These are available in cardboard or foam, depending on the application. Alternatively, you could use our Airsac inflatable packaging. It offers great protection and can save you space as it’s stored flat. |

You’re shopping thousands of small plastic parts a day |

If you’re manufacturing and shipping small plastic parts like mouldings or spares, grip seal bags are a good option. Grip seal bags are available in a huge range of sizes to suit your needs. Plus, you can customise them with coloured film or branding. These can be one of the less labour intensive ways of packing smaller parts, and can even be used for storage purposes as they take up minimal room in the warehouse. |

Is the volume of product you’re shipping out increasing? You might want to consider the possibility of introducing auto-bagging systems into your pack line. |

Do you need help getting the packaging essentials right?

If you’re a plastics manufacturer and have any questions about your ‘packaging essentials’ get in touch. You can call us on 01902 496 666, email us or complete our contact form to book a site visit with an expert today.

- EED/BDO Regional Manufacturing Outlook 2017

- UK Manufacturing Statistics

- Manufacturing in the Midlands: The Engineer Article